Profitability in poultry production can only be optimized when everything goes right, and that includes keeping the birds healthy.

Hygienic Water supply system is one of the most important key factors for good health and growth of poultry. It is important for water to remain hygienic all the way until it reaches the birds, and so water & drinker lines hygiene must be a focus of attention for the farm. Water lines should be thoroughly cleaned and sanitized at regular intervals.

1. Adjust drinkers to correct height

2. Fix leaks

3. Look out for air locks

4. Install a filter to prevent sediment build-up

5. Prevent bio-film by flushing

~ immediately after any intervention of medication

~ one minute for every 30 meters of pipe length

~ at least once a week

~ more than once a day during warm weather

~ use high pressure (1.5-3.0 bars)

6. Use high quality acidifier in water for desired pH level

Water source get contaminated with various organic and inorganic substances resulting in high pH thus chances of growing pathogens including salmonella sp., E. coli and fungi is high. Contamination of drinking water in poultry is formidable.

Generally it is recommended that optimum pH of drinking water of poultry should be around 4.5 to 5.5 and B value of feed should be low to maintain normal gastric pH of birds.

Since gastric pH is higher in chicks than in growers and adult birds, an utmost care should be taken during brooding period of chicks for:

-» Reducing chick mortality

-» Controlling E. coli, Salmonella and fungi

-» Improving FCR and weight gain

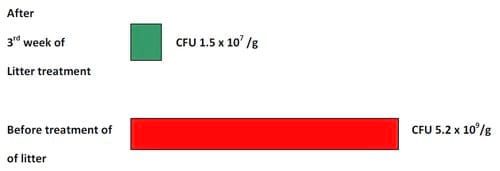

-» Reducing ammonia in litter

-» Reducing moisture in litter

To take care of the routine problems of poultry farm, we add sanitizers, acidifiers, medications, nutritional supplements & vaccines etc without understanding chemical interaction into the water which itself comes carrying its own baggage of organic & inorganic material.

We will have to keep in mind that while some chemical interaction could be synergistic, actually helping one another to work better but in the mean time making wrong solution may create problem by reducing effectiveness of the additives and some time leading to hazardous effect to birds & environment.

Following are some action & interactions which we must understand while preparing drinking water to poultry:

☞ Hydrogen peroxide (H₂O₂) and Chlorine (Cl) are not compatible so should not be used at the same time. Both are oxidizer and they will turn on each other.

☞ Copper sulfate is not compatible with Chlorine (Cl) however Copper sulfate which is an antimicrobial & antifungal agent actually enhances the effectiveness of H₂O₂ so they can be run at the same time with separate medicators.

☞ Organic iodine (Not the inorganic) is very compatible with Chlorine. This combination can help to prevent a full-blown respiratory infection if it is used early enough to treat sniffing, a loose croupy cough.

☞ Iodine, like Chlorine, works better at a lower pH.

☞ Chlorine is not compatible with any compound that act as reducing agent which would include most minerals water additives.

For example, products that contain copper, sulfur or iron will tie up the Chlorine and make it unavailable to work effectively as a sanitizer.

☞ Antibiotic like Chlortetracycline & tetracycline works best in low pH range. If you have alkaline water, adding good acidifier liquid actually enhances absorption of these products. But product like Penicillin & Sulpha drugs works better in pH above 7 so turning off the water acidifier during medication with penicillin & sulpha group is recommended.

☞ Vaccines are typically protein so at any time vaccines are used in water, the water pH should be above 4.

☞ All sanitizers lose efficacy at colder water temperatures. Chlorine, chlorine dioxide & peroxide/ozone are all temperature sensitive so colder water will slow down their reaction time.

☞ Peroxide is strong oxidant and contact with personnel is extremely dangerous. Peroxide deteriorates gradually even when stored correctly.

☞ There would be slime blooms in water system after the use of antibiotics. The antibiotic disrupts the microbial population in waterline system just as it does in the GI tract, allowing microbes such as yeast & mould to grow undisturbed.

So, thorough cleaning of water pipeline system to remove the slime using VIROK-H2O with high pressure flushing water routinely is recommended as & when required.

Regular use of best quality acidifier in fresh drinking water of poultry farm will solve routine problems but it should have following traits:

- Ability to reduce pH of drinking water as well as GI tract content.

- Should reduce B-value of ingredients for improvement of digestion & assimilation.

- Must suppress bacteria that are “pH sensitive” like E.coli, Salmonella, Campylobacter, C. perfringens, Listeria etc.

- Must work in fore gut as well as in hind gut

- Should be stable in all pH ranges.

Make sure that you are using perfect hygienic water for your birds and not a complicated solution.

NOTE : – For better hygienic water having pH 4-6 to eliminate virus bacteria & fungus in drinking water you may use VIROK- H2O which also help in removing biofilm from water supply channels.